The more things I learned and tried, the more things I don't know.

It looks like we are always using something as granted. But we are actually using the "default setting" for most of the machines. We followed the user's guide, and we did as we told to do. Therefore, we thought we know it. But things are not so straightforward.

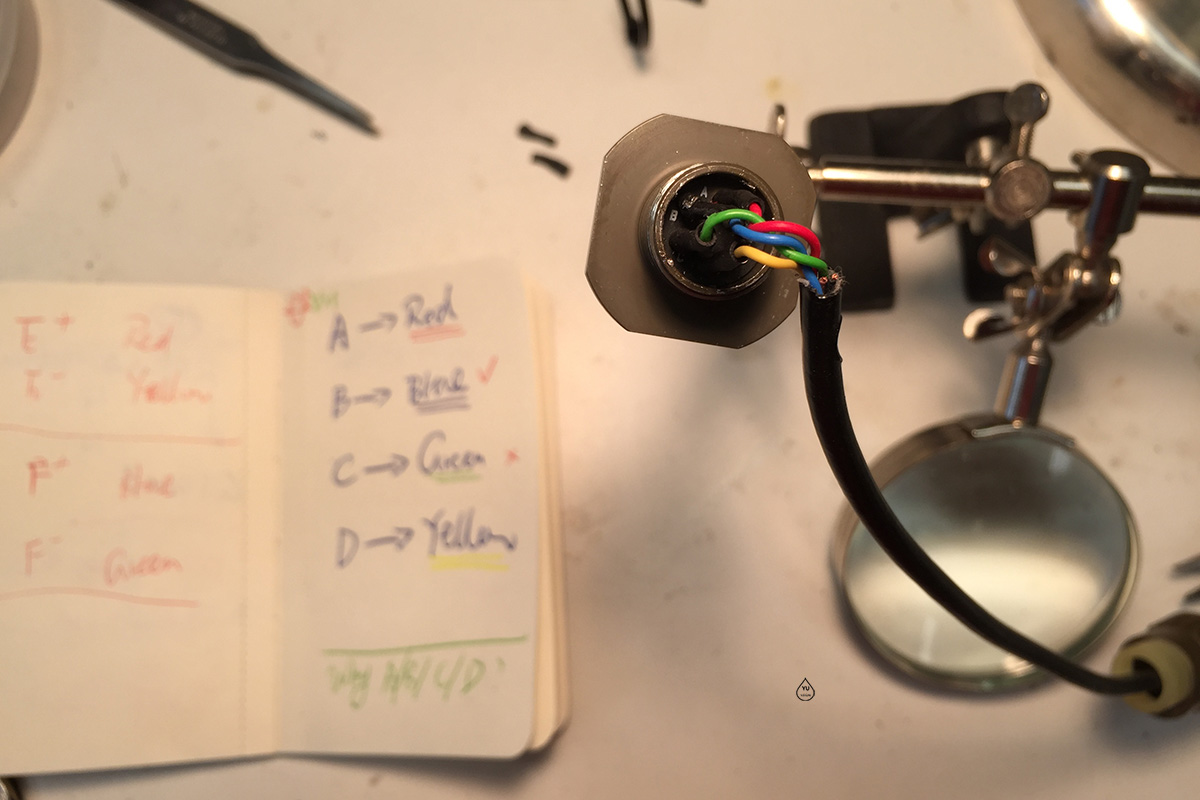

I had a chance to do some soldering activities, which is a basic operation of an electrical engineering. Even I was still do as I was told, but at least I knew something different from what I learned before.

The objective was to rewired the wires and soldering them. The soldering steps included:

-

Removing the solder on the connector. Use heated soldering iron to melt the metal alloy and remove the wire.

-

Soldering the wires. Find the right wire configuration, for example the pin A should be connected with the Red wire in this case.

-

Don't forgot the shrink tube. Each wire should have a shrink tube at the connection, so it can act as an electrical insulator.

I was just an assistant for Rob. He is the main operator. But I was a good helper during the step 2. Because the pin was so small, it not easy to inject the wire into the pin. Well, it is something like a preparation before sewing. You need to put the thread into the eye of the sewing needle, before you fix a small hole or a rupture on your cloth.

Happy birthday, "Yu Vision". It is your 4th year.